Company: BoMill

Website: www.bomill.com

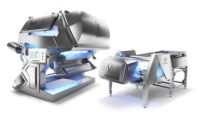

Equipment Snapshot: Benefiting from years of experience and feedback from customers and the grain industry, the company has developed BoMill InSight, the next generation industrial grain quality sorting equipment.

With its innovative patented sorting technology, using near-infrared transmittance (NIR-T) spectroscopy, BoMill InSight reduces waste and loss of valuable quantities of grain while making industrial processes more efficient.

“We are globally facing challenges related to the grain supply as well as implementation of stricter regulations, which emphasizes the need for technologies that offer new capabilities. I am excited to see the result from the development of our new BoMill InSight which offers the grain industry and food processors unique opportunities to capture the hidden value of grains while helping reduce waste in the value chain. With an attractive return on investment and scalable capacity from 2mt/hour up to 15mt/hour, our next generation industrial sorting equipment opens up opportunities to capitalize on the interest we have received from large grain processors and at the same time offer a competitive solution where lower volume is needed.” says Andreas Jeppsson, CEO of BoMill AB.

Following the next step, after the development of its overall design, the verification and confirmation of all its functionalities, BoMill InSight is now entering its industrial field-testing phase in collaboration with the Swedish grain mill Lilla Harrie Valskvarn, part of the Pågen Group, the market leading bakery in Sweden. The results of the field test will then pave way for the continued launch of the equipment. In parallel, the company is ready to start promoting and selling BoMill InSight to its targeted markets.

The BoMill InSight brand illustrates the unique ability of the equipment to uncover what cannot be seen, by looking inside each single kernel and sorting each individual kernel according to its internal quality parameters, at industrial speed. BoMill InSight will allow grain processors to sort commercial lots, on a large scale, according to quality parameters they could not act upon before.

Based on BoMill’s proven quality sorting technology using Near-Infrared Transmittance (NIR-T) spectroscopy, BoMill InSight is built on a new technological platform developed with versatility and low total cost of ownership for the customers in mind.

Its modular design, composed of a light and sturdy frame with up to eight sorting modules, allows an efficient set-up and installation to suit different configurations, low utility consumptions, simplified maintenance to maximize customers’ uptime, and an upgradable capacity to suit customers’ future needs.

With a flexible sorting capacity from 2 and up to 15 mt/h (equivalent to about 125,000 kernels analyzed per second) responding to highly demanding industrial standards, BoMill InSight addresses the sorting needs of all types of grain processors where internal properties such as protein level, fusarium contamination, or vitreousness are of interest for process and supply chain optimization.