The Bottom Line:

- Products should not be overweight or underweight

- Metal detectors are important for finding foreign objects

- Ensuring products are safe for consumption is vital

Quality control (QC) and quality assurance (QA) are vital in the snack and bakery world. Checkweighers, scales, metal detectors, X-ray systems, and vision systems all help products land in consumers’ hands free of defects.

Top QA/QC concerns

Todd Grube, product manager, inspection systems, Heat and Control, Hayward, CA, says top QA/QC and food safety concerns involve foreign materials (metals, rocks, glass, plastics).

“Because products, raw materials (and their sources), locations, and equipment can vary greatly, bakery or snack producers need a variety of approaches to ensure that their product is uncontaminated and safe,” he says. “Finding an inspection equipment provider that offers a test run can help a bakery or snack producer determine if a basic metal detector is adequate.”

For example, if non-metallic foreign materials are an issue (packaging materials contain metallized film) the producer should consider adding X-ray machines, he suggests.

“As the technology in inspection and detection equipment continues to advance, bakery or snack producers should evaluate the level of their quality control program and, if necessary, utilize more sophisticated inspection equipment that detects smaller foreign objects, reduces false rejects, and handles a wider range of products to assure maximum food safety with higher productivity.”

Michael Carroll, business development manager, Loma Systems, Farnborough, UK, says inflation is bringing product waste into focus. The elimination of waste/giveaway now has a more significant impact on the bottom line.

“[Checkweighers] ensure upstream equipment is not overfilling and can communicate with other processing equipment to adjust the fill levels and reduce giveaway/waste. Moreover, [our] systems have ‘x-weighing’ capabilities to measure if products are overfilled or underfilled based on patented algorithms that make calculations using density analysis,” he says.

Adam Peliska, check weigher machinery sales representative, Yamato Corp., Grafton, WI, says QA/QC equipment ensures shelves are stocked with accurate packages and that products inside are safe for consumption.

“Snack and baking customers’ top QA/QC and food safety concerns are related to sanitation, package accuracies, and keeping product free of contaminants and/or foreign objects. These concerns aren’t necessarily new; however, today, customers’ standards and expectations are higher than ever before. Deviation from these higher standards is no longer being accepted,” he explains.

“The best equipment suppliers develop and improve their products to match these higher expectations –-maybe even more than the customers need—and they address sanitation, accuracy, and food safety head-on. Today’s customers do not want to make any concessions when it comes to their QA/QC equipment, nor should they,” Peliska adds.

A clean packaging environment helps ensure food safety, reducing the risk of product contamination, he says. Specific to sanitation, customers expect QA/QC equipment that is fully washdown with a design that minimizes dust accumulation.

Accuracy may be a more obvious concern but is still important, he suggests.

“Something to consider is that an accurate package is not only related to weight, but it is related to food safety as well—specifically, food safety as it translates to nutritional values. While package underweights are never legally allowed, the amount of product inside a package directly impacts nutritional values,” Peliska comments.

“Sending overweight packages to store shelves with too much food inside that does not match the nutritional information on the label on the outside opens snack and baking customers—and consumers—up to major risk. Consuming too much of a food product may be problematic for people who suffer from health-related issues like diabetes, for example, and snack and bakery companies could be held accountable,” he says.

“Beyond sanitation and accuracies, snack and baking customers must, of course, be concerned about keeping packages and products free from foreign objects. Having the ability to integrate metal detectors with QA/QC equipment helps ensure the food products are safe to eat,” Peliska finishes.

Barry Voorhees (production manager, metal detection, Bunting, Newton, KS) agrees, saying foreign contamination is always a concern in food production—which is why critical control points (CCPs) are important.

“Having the best sensitivity possible at those CCPs is vital to their operation for consumer and brand protection. The smaller the particle is that can be seen the better. What will vary by aperture size, product signature, etc., which are the typical variables in these applications. It is also critical that they check incoming ingredients and in process as well—not just relying on the end of line CCP locations to check for contamination. Having proper magnetic and metal detection systems in place throughout the process is always best practice,” he explains.

Eric Garr, regional sales manager, Fortress Technology Inc., Toronto, Ontario, says whether it’s gluten-free products, single-serve portions, large packs, or better-for-you products, snack and bakery manufacturers must evolve and meet consumer demands.

“Regardless of changing tastes, the primary concern for operators must always be food safety. The addition of new ingredients, flavors, own-label, sub-brands, pack sizes, and nutritional concepts means that a snack company’s average portfolio can easily comprise 100+ stock keeping units (SKUs),” he notes.

“Metal detectors, checkweighers, and X-ray inspection systems are essential to the production process; however, producers need to ensure their inspection solution is sophisticated enough to inspect different kinds of food products, but also different types of packaging,” Garr recommends.

The ability to efficiently inspect high-value ingredients of varying size, characteristics, and densities within products is always a high priority for purchasing inspection equipment, he says.

“Quality managers on these processing lines need inspection machinery to perform reliably with minimal downtime, yet also reject contaminated products accurately, without incurring high levels of false rejects. For loose and raw products, such as potato chips, cereal, corn, popcorn, and snacks, inspection CCPs will often take place before the bagging stage using a metal detector, and then later down the line when bags are sealed, just before packing into boxes for distribution,” Garr adds. “The reason for this is leaving it until the end of the production line could result in high levels of false rejects and unnecessary disposal of good product and packaging. In addition, packaging for snack foods is typically metalized film, which can limit the performance of a metal detector.”

Another way to mitigate finished-product rejection is to inspect ingredients before the processing stage. Here, bulk gravity and large bag inspection systems are usually installed to QC incoming dry ingredients, he says.

“This can be advisable in bakery processing facilities for a number of scenarios. Firstly, producers will want to identify the source of any metal contamination, which can include raw ingredients, e.g. flour. Secondly, any contaminants will be detected and rejected in their largest form before processing, typically resulting ejecting more metal out of the process with far fewer rejects compared with only inspecting a finished or packaged product. This may come down to the aperture of the metal detector or the relative sensitivity obtained with unprocessed and processed ingredients. It also helps to mitigate damage to processing equipment, e.g. grinders,” Garr expands.

Performing supplier weight checks at this early phase is also advisable, especially given raw ingredient costs, he explains. To comply with production standards, bakery and snack manufacturers also need appropriate, effective testing systems for the audit process of industrial contaminant inspection machines.

“Depending on the criteria set out by each retailer Code of Practice (COP), tests are typically scheduled throughout the day at hourly intervals to confirm the inspection system is consistently and reliably detecting and rejecting the certified metal test samples. If carried out manually, passing test samples through the exact center of a standard 6.5-inch or 8.5-inch aperture, when product is being funneled at high speed from a multi-head weigher through the metal detector straight into a VFFS bagger, and retrieving them is huge challenge and drain on labor,” Garr says.

“Not to mention that testing in the geometric center of the aperture is seldom achieved, as the plastic funnels common in this application, more often than not, direct the test samples closer to the aperture walls where it will be drastically easier to detect,” he elaborates.

“Next on the line, bakery and snack processors should perform product verification weight checks. Not only does this help ensure product quality and compliance with weight legislation—rejecting out of tolerance packs—these weight checks can also reduce product waste and giveaway,” Garr says.

“Lastly, at the end of the processing line, packaged products are inspected after packaging and before leaving the facility to ensure food safety, protect consumers, and safeguard brands. These inspections are typically performed on single or multi-line conveyor metal detectors, ensuring compliance with legislation, retailer codes of practice, and food safety standards.”

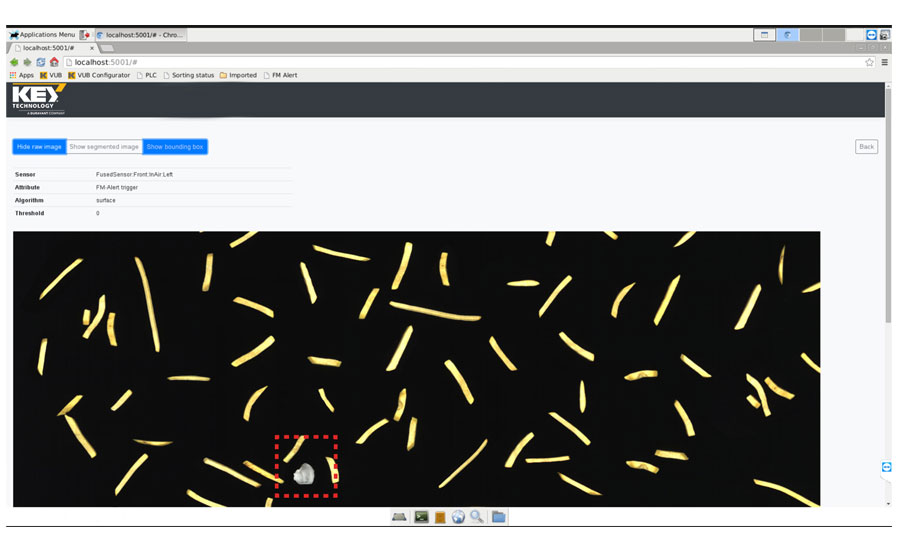

Marco Azzaretti, director of marketing, Key Technology, Walla Walla, WA, says top QA/QC and food safety concerns in snack and bakery are improving sanitation to reduce the risk of bacterial contamination, and eliminating foreign material (FM) in the product stream. Finding and removing product defects is also a concern.

John Klinge, global product manager, metal detection, Eriez, Erie, PA, says traceability is important in QA/QC world for snacks and bakery items.

“Having traceability in material used and batches produced is very important. If a problem arises with a certain lot of material, hopefully batches or shorter production runs of products can be put on hold or quarantined versus massive production runs of product. Metal detectors can save product settings for certain batches. You can verify the metal detector by batches,” he says.

“Equipment suppliers are incorporating sanitary/hygienic designs as a standard. It’s important that the mechanical design of a piece of equipment is easier to clean using minimal tools. This minimizes downtime and encourages operators to clean if it’s ‘easier to do,’ Klinge notes.

Per Klinge, other QA/QC issues include:

- Foreign contaminant removal: Magnets should be used with metal detectors. This is important, he says, as magnets separate mild steel and work-hardened stainless. Metal detectors detect all metals and “metal detectable rubber and plastics.”

- Plastic and rubber components should be “metal detectable: Metal-detectable plastics and rubber in product zones: zip ties, scrapers, belting, O-rings.

- Minimize foreign contamination from entering process: Companies should have a strict policy of barring jewelry, items in pockets, non-metal detectable pens, etc. from entering production areas.

- Possibly less of a concern, he says, is automating more processes to minimize handling and human interaction with the product. “For example, using automatic rejects with a metal detector vs relying on an operator to remove a contaminated product from the product stream or conveyor belt. Another example: using auto clean magnets vs manual clean magnets. Folks are looking to ‘design out’ risk wherever possible.”

Mark Navin, vice president of sales, Spee-Dee Packaging, Sturtevant, WI, says more than ever consumers read food labels, scanning for allergens and other ingredients they want (or don’t). This has put an emphasis on making machines easier to clean and faster to change over.

“Tool-less change parts, easy access hoppers, and complete product contact swap out parts are a few ways that equipment manufacturers have addressed these needs,” he notes.

Paolo Tondello, application specialist for leak detection and gas sensing, Antares Vision Group, Mount Laurel, NJ, says maintaining food safety is paramount for consumer health as well as business success.

“Fortunately, modern equipment makes it less difficult to follow food safety processes and align with food industry standards,” he says. ““[To start], X-Ray units and metal detectors can inspect for foreign bodies. The most sophisticated X-Ray devices can find miniscule foreign matter both before and after packaging.”

“Another automated inspection godsend is micro-holes detection, which is invaluable for product in modified in packaging, especially for products in modified atmosphere packaging (MAP), which require a tight seal to ensure shelf life,” Tondello adds. “Another solution is seal integrity checking, which utilizes camera inspection of the sealing area to make sure nothing (especially the product itself) is preventing a firm, lasting seal.”

“At the end of line, checkweighing helps brand owners not only ensure that products are consistent, but prevents waste insomuch as it ensures that an overage of product isn’t being ‘given away’ for free.”

Data collection and analysis

“Data capture is critical for quality control,” says Carroll. “Loma Systems checkweighers are designed to track/capture the trend of product weights to flag if upstream equipment is starting to over/underfill products. Data capture is also essential for determining what lines have high reject rates. This can inform producers if there are other areas/pieces of equipment in their production processes that need calibration and/or review.”

Additionally, capturing data on contamination discoveries, whether via metal detection or X-ray technology, can help inform producers which production lines may need to be reviewed and/or additional safety measures need to be implemented, he adds.

Peliska says data collection provides proof of package accuracies and further ensures food safety.

“The QA/QC equipment snack and baking customers use in their facilities should include some kind of data-collection capabilities. This data can be incredibly beneficial when tracing packages and conducting audits. Further analysis of all the data collected can be applied when implementing process improvements,” he shares.

“If there is a faulty product, the historical data collected by the checkweigher can trace that exact package using the recorded time of when it passed through the QA/QC equipment. The ability to audit each package further protects the customer, as well as consumers, by ensuring the packages being sent to stores are accurate and the food inside is safe for consumption,” Peliska expands.

“When upstream equipment has consistent errors, QA/QC equipment should also have the ability to communicate with it—stopping it completely to prevent the error from happening consistently,” he explains.

Voorhees says with a metal detection system, every event must be recorded. Making this information easily accessible to QA/QC personnel is important.

“These logs can be accessed in a variety of ways, from viewing the information live on the unit’s display, to downloading to a USB at the machine, to complete networking options. With our 07 controller we offer Automatic Protocol Exporting which allows the detector control to back itself up to a specific designated location on the customer’s network. This allows them to review any reports that have been saved from their desk. There are a variety of trigger settings to define this occurrence,” he notes.

“We also offer a server-based option which allows the customer from a web browser at their desk to view the systems live from their office, as well as run reports, etc. We can also do other networking options to tie directly into their control system for data capturing as well,” Voorhees adds. “We are always looking for ways to incorporate equipment, ultimately making it easier for not just the quality personnel, but also the operators, to perform their duties.”

Garr says the industry is entering a new internet of things (IoT) era where everything that can be connected, will be. Melding data extraction into a larger performance picture and bridging the gap between machines and humans to help predict, rather than react to, myriad production scenarios is critical for improving processes and food safety.

“One of the key things to consider with paper records are the higher risks. Not only can manually collated information be incorrectly recorded, forgotten or lost, results can also be deliberately falsified. If producers cannot prove when and where inspection of their products took place, the manufacturer may then be unable to demonstrate HACCP compliance and could be forced to re-inspect an entire batch. This not only slows down production; at worst, it could trigger a product recall,” he suggests.

“To assist customers gather real time data, Fortress digital conveyor, gravity, pipeline, and combination metal detectors are equipped with optional machine sensors to run signals between everything from reject confirmation, to bin doors, air pressure, infeed and encoders, and more. Deploying more sensors naturally generates more intelligent machine, fault and process data. All of this data can be viewed in Contact Reporter, resulting in a more failsafe and smarter inspection system,” he shares.

Azzaretti says placing inspection systems and sensors before and after critical transformative steps such as frying and baking allows producers to collect valuable, useful data.

“The data can be harnessed to track and report on the quality of incoming product by shipment and/or supplier, maximize raw product utilization, and fine-tune line processes to achieve higher operational efficiencies,” he says.

Klinge notes a robust HACCP program is essential; this proactive/preventative approach looks for potential problems and ways to monitor or design them out.

“What’s important is to make sure there is a scheduled time to review and conduct the analysis again. Technologies change, processes change, new best practices are developed, and different or fresh sets of eyes can help identify areas to look at,” he recommends.

“Once CCPs are identified, they should be monitored. Ideally, there are CC points throughout the process to better help to pinpoint an area of concern versus not knowing where to begin. For example, magnets and metal detectors should be in place throughout the entire process to better help pinpoint where metal contaminants are coming from,” Klinge says.

“Magnets and metal detectors at the beginning of the process to prevent foreign metal from entering the process, magnets and metal detectors after critical processes such as slicing or screening, and magnets and metal detectors at the end of the process as the ‘final check,’” he notes.

“Folks want to know as much info as possible, for example, preventative maintenance (PM) recommendations from the equipment suppliers. Maintenance teams are smaller and stretched very thin. Companies are relying on the OEM suppliers to help train operators and service the equipment. It’s critical that end users work hand in hand with OEMs to develop PM schedules, have a robust critical spare part inventory, all in an attempt to minimize downtime,” Klinge expands. “This is an important area that is sometimes overlooked because folks are so busy and stretched to the limit. Work ahead to prevent equipment failure. This proactive work will pay dividends over time,” he predicts.

“The more data is collected on the process, the easier it is for companies to find trends in the data to help identify problems within production. For example, between 3–7 a.m., our metal detector always goes off. Analyzing data can help identify why, and remote monitoring using a PLC and software can help to automate this process,” Klinge shares.

“The other important discussion point is data collection of employees when it comes to using the equipment. Equipment should have the ability to create specific users with unique passwords. This gives companies traceability within their own organization. All of this data will help companies develop continuing education and training plans.”

Tondello says if an owner has a process in place, common sense dictates it is best to understand how that process is performing.

“The most effective way to do this is via data collection and analysis. Data collection opens the door to precise, detailed insight into potential production issues well before they become a line-stopping flaw; in other words, it gives a preview into a looming problem and allows manufacturers to correct for simpler, minor issues rather than complicated, major ones,” he explains.

“Track-and-trace management software can automatically aggregate data to reveal performance trends, line efficiency, etc. Among other issues, it can help identify weak spots on a production line that minor tweaks can alleviate, preventing bottlenecks and promoting ongoing production optimization,” Tondello adds. “It will become more common for track and trace to expand from the production line to the supply chain, allowing brand owners to monitor its products’ journeys to their final destinations. This injection of accountability will help strengthen supply chain security, warehousing personnel performance, etc.”

Navin recommends closed loop systems between packaging and processing, which are increasingly common.

“Data collected from the packaging line can be used to inform processing changes with the product. For example, if package weights are trending downward at the packaging stage, this data can be sent to processing to make changes to the upstream system to make a correction before packages reach a point of being rejected,” he shares.

Grube says typically metal detectors and/or X-ray machines are found at the end of processing lines to ensure packages contain uncontaminated product. After monitoring data, producers may decide to add detection earlier in the process to minimize product and packaging waste by reacting to an alert before it impacts more product.

“Adding inspection equipment to the front of production lines, such as inspecting incoming ingredients, will ensure that no metal contamination or non-metallic foreign materials enter the process where it could damage equipment and/or be broken down into smaller pieces that may go undetected at the end of line inspection,” he explains.

“Front-of-line inspection can typically be accomplished with smaller apertures that have better sensitivity than at the end of line where the aperture size may be much larger to accommodate the packaged product. Many data collection software packages can also provide a precise date and time stamp of the detection and other specific details related to the detection event. This information can aid in identifying the root cause of the contamination, and what can be done to reduce future events.”